Home / All About Silencers / Cleaning a .22 Cal Suppressor with a Soda Blaster

Home / All About Silencers / Cleaning a .22 Cal Suppressor with a Soda Blaster

Cleaning a .22 Cal Suppressor with a Soda Blaster

Jason Baird

This blog article is a follow-on to my previous article, “Sparrow 22 Suppressor Cleaning: 3 Types of Pretreatments,” so if you haven’t read that one it might behoove you to do so before you read this one. I originally intended for this article to feature using a soda blaster to clean the Sparrow 22. On a trip to SilencerCo, my tour guide introduced me to soda blasting for suppressor cleaning. He also let me shoot the Switchback 22. So, I decided to include cleaning the Switchback 22 in this article, too.

Grit Blasting

For those who don’t know anything about it, I’ll briefly address abrasive grit blasting. For additional information, search for “grit blasting” on the Web. Industries use grit blasting to clean surfaces for inspection or coating. As one might assume from the name, grit blasting uses high-pressure air to entrain an abrasive medium (the grit) and propel it at the working surface.

More About Grit

Grit types range from soft (sodium bicarbonate, or soda) to very hard and tough (carbides). Soda is good for paint removal, though. In fact, soda blasting cleans the carbon and some stuck-on metals from suppressor surfaces. It doesn’t damage the surface as easily as harder grits.

The blasting soda process typically uses small particle sizes, 150- to 3400-microns in diameter. For comparison, the particles in the type we have in our kitchens for cooking, etc. are quite a bit smaller, at 65- to 70-microns. Generally, the smaller the particle size, the gentler the stripping effect and the greater the dust cloud created by the blasting process. The larger particle sizes create less dust and remove material from the surface faster. Large particle sizes are more expensive to buy (see this article regarding soda blast cleaning).

The Sand Blaster Set-Up

I have a sandblasting cabinet and a portable sandblaster in my shop. I didn’t want to go to the trouble of switching back and forth between sand and soda as blasting media in the cabinet. Repurposing a soda blast system to sand might be OK, but the reverse just asks to get a little sand grit mixed-in with the soda – bad juju! Without special dust collection equipment installed, a blast cabinet purposely recycles the grit; the grit falls back into the hopper after it hits the working surface. Soda particles break down into dust when they hit the working surface, so recycling them through a blast cabinet system would rapidly result in a massive FAIL, with no work done on the surface by the blasting medium.

What You’ll Need to Sand Blast a Suppressor

In the following explanation, I give links to items online at the time I wrote this post. However, the sellers may no longer have the items, so this information is for comparison purposes only.

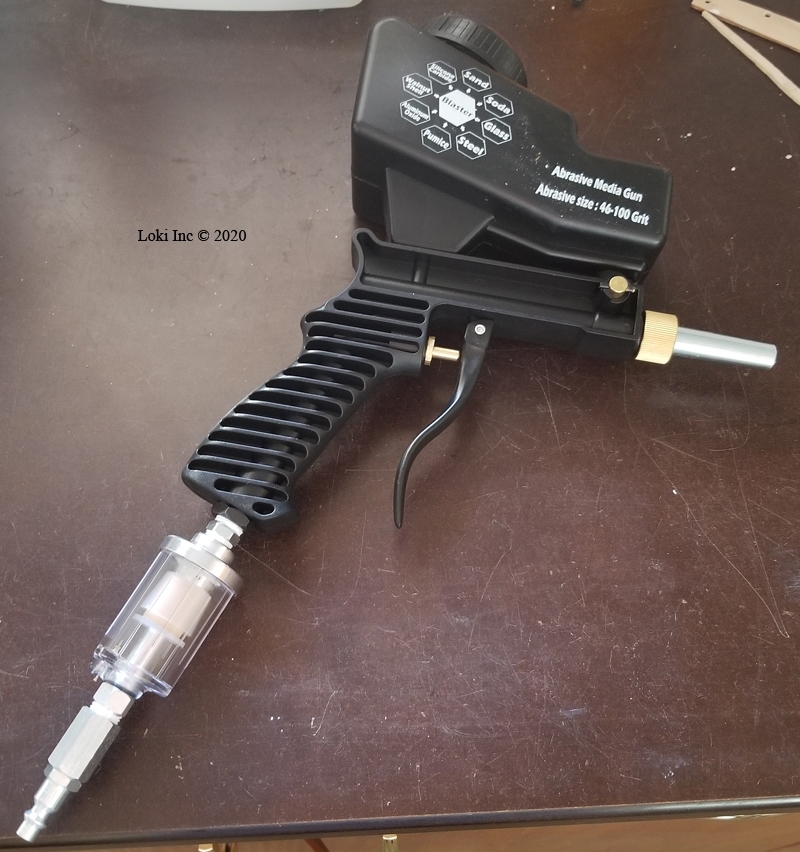

To grit blast, you need a hopper for the grit, a source of high-pressure air and a nozzle system that draws the grit into the air stream. It should accelerate the air/grit mix toward the working surface. The simplest blasting system consists of the hopper and nozzle system, combined.

I ordered a simple one online, along with an air dryer since I planned to use the blaster with a large air compressor that usually pushes some water into the air hoses.

Note that the company selling the blaster recommends an air source that can maintain 90- to 150-psi pressure at a minimum 4-cubic-feet per minute volume. With this blaster, the hopper sits above the nozzle and trigger assembly so the grit gravity feeds into the mix. Other blasters might use a hopper or reservoir that draws the grit through a tube into the nozzle assembly.

Baking Soda

At the time I purchased the grit blaster, the soda blasting media was out of stock everywhere I looked. I purchased three, one-pound boxes of baking soda at the local grocery store to use as media.

Good Old Baking Soda

Even though most online references say not to use baking soda because of its small particle size, it worked well for me in my soda blaster (see the results, below). Later, I was able to get a deal on a 20-pound bucket of soda blast media online. I’ll give you the source, but shop around as the prices and deals change constantly. In fact, if you have one of the big chain home improvement or farm and home stores nearby, you may find the soda blasting media at one of those places for less than online prices.

OK, but does soda-blasting work?

Yes, it does, and quickly!

- First caveat – you must have access to compressed air that meets the requirements to operate whatever soda blaster you use.

- Second caveat – soda blasting removes paint and surface finishes, so do not use it on suppressor parts that have some sort of coating or finish that is not part of the metal. Exercise some common sense. Do not use abrasive grit more aggressive (harder) than soda!

If you are cleaning a .22 cal suppressor, you should be able to disassemble it by design. Use soda blasting to clean internal parts, but do not attempt to clean exterior parts that have a coating or finish. Use the proper PPE for your process! Soda blasting creates a nuisance dust of sodium bicarbonate. Therefore, the impact of the abrasive particles on your skin stings and the escaping air from the blasting process can be loud.

What to Wear While Soda Blasting

So, wear safety glasses or a face shield and hearing protection, if required. Also, I’d recommend wearing a filter mask that stops nuisance dust if you are indoors or in a situation outdoors (no wind) that keeps the dust cloud around you. Don’t forget to wear protective gloves, because you’ll have to hold the small parts as you blast them. After you are done, unless you use an enclosed cabinet you will likely have soda dust on parts of your body, so brush or rinse it off. In our litigious world, realize that no matter what you use to clean the bullet metals off your suppressor, you will have some small amount of lead to dispose of as a residual. Also, realize that soda has a pH of 8, so if you soda blast around acid-loving plants, the dust that settles on them may damage them.

Another Look at a Dirty Sparrow 22

If you don’t remember what a dirty Sparrow 22 looks like, take a gander at Part 1 of this blog series and you’ll see several photos. Here’s what the Sparrow 22 looks like after about 5 minutes with my soda blaster

.

More About Cleaning with a Soda Blaster

I used the soda blaster outside with a breeze at my back, in a place where the soda dust wouldn’t damage my grass (it needs to be limed, anyway).

What about the kitchen baking soda that I used being too fine to work very well? It was “dusty,” but I couldn’t tell that it was any dustier than when I used the soda blast media. The baking soda worked fast and cleaned the surfaces well, as you can see from the photos. I disassembled the Switchback 22 and used the soda blaster on it, too, with great results

Conclusion: I’m sold on cleaning .22 cal suppressors using a soda blaster!